The Hierarchy of Controls & Workplace Safety from Chemical Hazards

October 14, 2020

What is the Hierarchy of Control?

The Hierarchy of Controls is a concept for implementing practical and effective control measures for hazards in the workplace. When a hazard is identified in the workplace, controls need to be put in place to manage the potential risk to workers who interact and work around the hazard. For example, let’s say a chemical is the hazard in consideration. The chemical hazard would require one or more controls to manage and prevent any potential harm to a worker via an exposure to the chemical.

The Hierarchy of Controls is widely endorsed by regulations, policy statements and chemical hazard management systems in an effort to increase worker protection.

How Does the Hierarchy of Control Work?

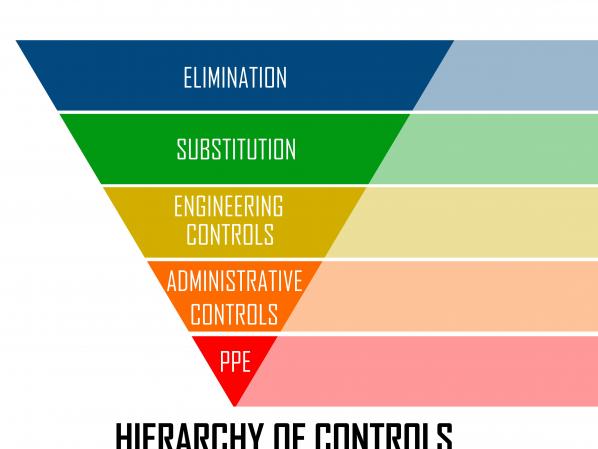

The Hierarchy of Controls is an inverted pyramid. The shape emphasizes that the hazard control methods at the top of hierarchy are more effective at protecting workers from chemical exposure compared to the hazard control methods at the bottom of the hierarchy.

The hierarchy of controls is a generally accepted method for hazardous chemical management to reduce harm and the risk of illness or injury. Applying the appropriate level of controls for the hazard is important for safeguarding workers. When looking at controlling a chemical hazard the process should always begin at the top of the hierarchy of controls and work down choosing one or more methods of control.

What Are the 5 Hierarchy of Controls?

The 5 hierarchy of controls are:

-

Substitution – replacing a chemical hazard for another that is of lower risk.

-

Administrative controls – changing workplace practices to reduce exposure.

-

Personal Protective Equipment – protecting workers from chemical hazards with PPE.

Elimination of Chemical Hazards in the Workplace

Elimination of a chemical product means getting rid of it entirely. The best way to remove a chemical product is to ban, prohibit or restrict it at the worksite. You can eliminate a chemical hazard before it gets onsite or afterwards by removing it from the physical chemical inventory. When you remove the chemical, you remove the hazard. The elimination control measure works best in the design phase of a project or task.

Substitution of Hazardous Chemicals

The next most effective means of control is substitution. Substitution means to replace one chemical for another with lower physical and health hazards. Finding an effective chemical substitute may take some effort but it is worth the return on worker health.

While Elimination and Substitution are the most effective methods of controlling a hazard, it may not be possible to use either control method. Products that are manufactured or produced in-house cannot be eliminated or substituted. However, there may be some flexibility in the additives used to make your manufactured products. Shop supplies, like lubricants, cleaners, degreasers, paints, or solvents, are often the easiest to substitute.

Engineering Controls for Chemical Hazard Management

Engineering Controls protect workers by reducing hazardous conditions or by adding a barrier between the worker and the hazard. There are three general types of engineering controls that can be used to manage chemical hazards:

-

Natural ventilation

-

Local exhaust ventilation

-

Containment.

Well-designed engineering controls for hazardous chemicals can be highly effective and be independent of workers actions.

Natural Ventilation

Natural or general ventilation refers to the dilution of contaminants due to the air flow into or out of a work environment. This type of ventilation is sufficient when the contaminants are not toxic, and the amount of contaminant generated is low. Natural ventilation is usually not the strongest engineering control and is not associated with removing contaminants away from a worker's breathing zone.

Local Exhaust Ventilation

Local exhaust ventilation captures contaminants near the source, away from the worker’s breathing zone, and exhausts the containment outside.

Containment of Chemical Hazards

Containment refers to a closed system to contain the chemical hazard like air-tight chemical drums, large storage tanks, or chemical process systems. It usually is used when the physical and health hazards are greater, and releases into the atmosphere are dangerous.

Administrative Controls to Reduce Chemical Exposure

Administrative controls are work practices designed to reduce the direction, frequency, and severity of chemical exposure. They are always used in conjunction with other controls to improve the effectiveness. Administrative controls often involve:

-

Chemical safety policies and standard operating procedures

-

Rules prohibiting certain behaviours in the workplace

-

Modified work scheduling

-

Restricting access to parts of the workplace

-

Decontamination procedures

-

Housekeeping

-

Hazcom signage

-

Health and workplace monitoring

-

Alarms systems

-

Training

Personal Protective Equipment for Workplace Safety

The final level in the hierarchy of controls is Personal Protective Equipment or PPE. PPE refers to protective clothing, helmets, eyewear, and ear protection, designed to protect workers from injury, illness, or infection. Respirators are also considered PPE. PPE can be too quickly adopted before other hazard controls are considered. PPE can be easy to implement but there are serious limitations that put the worker at risk of chemical exposure. Best practices must be followed to ensure PPE is being used effectively.

Administrative controls and PPE both require adherence to rules and significant effort by the worker. As we all know, extra work means shortcuts and resistance, reducing the effectiveness of the chemical hazard control.

What is the Most & Least Effective Chemical Hazard Control?

Since control measures at the top of the Hierarchy of Controls pyramid are more effective, elimination is the most effective chemical hazard control. As previously stated, the best way to protect against a chemical hazard is to eliminate it before it enters the workplace.

The least effective chemical hazard control is PPE due to the significant risks associated with not using it properly. While PPE can provide a physical barrier between the wearer and hazardous substances, it does not eliminate or mitigate the risks associated with chemical exposure at the source.

Implementing the Hierarchy of Controls for Chemical Hazard Management

The Hierarchy of Controls challenges us to think of better ways of controlling chemical hazards in the workplace. Monitoring the effectiveness of our controls brings the hierarchy full circle. Involving workers in the chemical management process of selecting and implementing controls is a predictor of their success.

If you are looking to elevate the occupational health standards for your organization, get in touch with the experts at Chemscape Safety Technologies today.